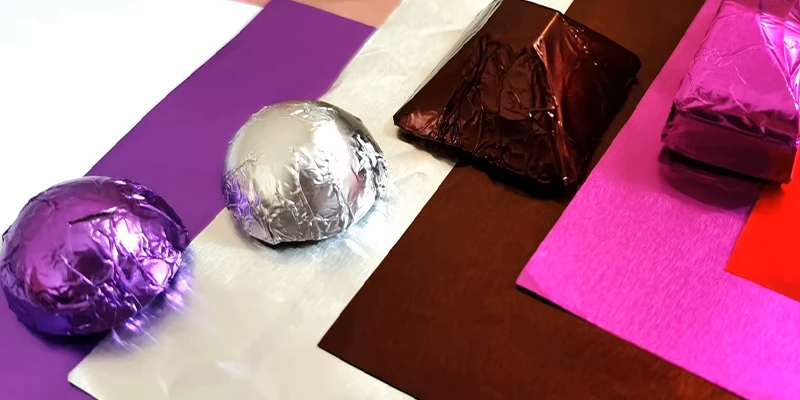

Chocolate foil wrappers are specialized packaging for chocolate and candy. Chocolate foil is gold and can prevent chocolates from getting damp and keep them dry. Also, this foil can withstand heat and prevent chocolates from melting.

In functional protection, foil wrapped chocolates effectively block moisture, light, oxygen and odors, keeping chocolate fresh and preventing it from melting or flavor deterioration. Wrapping foil for chocolate is not easy to tear and puncture, ensuring chocolate remains intact during transportation and handling.

Why Choose Custom Chocolate Foil Wrappers

Custom chocolate foil wrappers are very popular in the chocolate and candy industry. About 70% of consumers in the market will influence their purchasing decisions based on packaging design. Customized foils can make products stand out on the shelf or page through unique patterns, textures (such as gold/silver/rose gold) or craftsmanship.

Chocolate packaging foil attracts customers by customizing the company logo, color, pattern and texture. Unified colors, logos and designs can strengthen the brand, especially in scenarios such as holiday gift boxes and co-branded products. Aluminum foil barrier properties can reduce the “fat bloom” problem caused by temperature changes in chocolate, maintaining the taste and appearance. The shelf life of chocolates packaged in ordinary plastic is about 6 months, but in aluminum foil packaging it can be extended to more than 12 months.

The custom chocolate foil wrappers fits chocolate shape tightly, reducing damage and deformation during transportation. Food-grade chocolate aluminum foil is certified by FDA, EU 10/2011, etc. and is harmless to the human body.

Key Factor of Customizing Chocolate Foil

Custom chocolate foil wrappers—factors to consider when selecting them:

Material And Barrier Properties

Chocolate uses 8011 aluminum foil, which is low in cost and has stable chemical properties. It has sealing, moisture-proofing, light-proofing, and heat-insulating properties.

Foil thickness (7–30 microns) and tensile strength ensure resistance to tearing during handling or shipping. High-quality aluminum foil blocks moisture, oxygen, and UV light, preventing chocolate from melting, blooming (surface whitening), or flavor degradation.

Design And Branding

- Printing Techniques: Digital printing, hot stamping, or embossing.

- Finishes: Glossy, matte, or holographic effects to align with brand aesthetics.

- Brand Consistency: Incorporate logos, color schemes, and typography to reinforce brand identity across product lines.

Functional Performance

Foil wrappers must fit chocolate dimensions perfectly (e.g., truffles, bars, bonbons) to prevent slippage or exposure. Heat-sealable coatings or adhesive closures ensure airtight protection and freshness retention. And, foil should withstand varying climates, especially for global distribution.

Cost And MOQs

While custom foil costs 20–30% more than generic options, it drives 10–15% price premiums and reduces waste from damaged goods. Flexible MOQs allow small brands to test without overstocking.

Yongsheng Chocolate Foil Wrapper Manufacturer

Wholesale foodgrade chocolate foil wrappers for chocolate bars and candy packaging to save your cost. We Yongsheng, accept custom chocolate foil size and color. All our products have passed FDA and CE certification; you can ask us for a free sample to test.

Food Grade Safety And Protection

Our aluminum foil materials have passed food-grade safety certifications such as FDA, EU 10/2011, GB 4806, etc., with no risk of heavy metal migration, ensuring the safety of chocolate.

Triple barrier protection:

- Moisture-proof and oxygen-proof: The barrier rate is ≥99.9%, which prevents chocolate from softening or oxidizing and deteriorating due to moisture, and extends the shelf life to more than 12 months.

- Light-proof and anti-oxidation: The metal coating effectively blocks ultraviolet rays and prevents “fat frost” caused by oil oxidation.

- Tear-resistant: Using 7-30 micron thickened aluminum foil, the puncture resistance is increased by 40%, and there is no damage during transportation.

Cost Controlled

- Transparent price: The unit price of customized packaging foil is only 20%-30% higher than that of general-purpose foil, but it can support a product premium of 10%-15%.

- Reduced loss: Precise size matching and high-strength materials reduce the transportation loss rate to less than 1%, saving more than 50,000 yuan in annual costs.

- One-stop service: Full support from design and proofing to mass production, shortening the delivery cycle to 7-10 days, helping you seize the market opportunity.